|

Company Profile

|

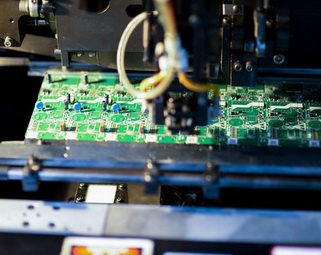

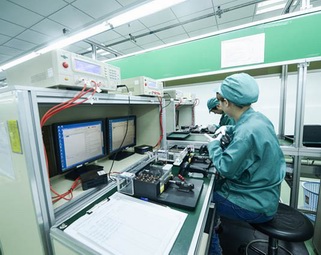

Manufacturing Facilities

Manufacturing Facility - Shenzhen

Total Floor Area: 32,000 Sq m

Total Building area: 40,300 Sq m    5 x Fuji(NXT) SMT Lines with AOI

5 x Yamaha SMT Lines

Temperature Cycle and Humidity Chamber

CMM Measuring Machines    Special equipment for manufacturing/testing of satellite TV

receivers    Anti-Static Substore

Manufacturing Capability SMT 0201 chip BGA 0.4mm ball to ball

Manufacturing Facility - Taishan

|

Plastic injection Machines

Plastic injection Machines